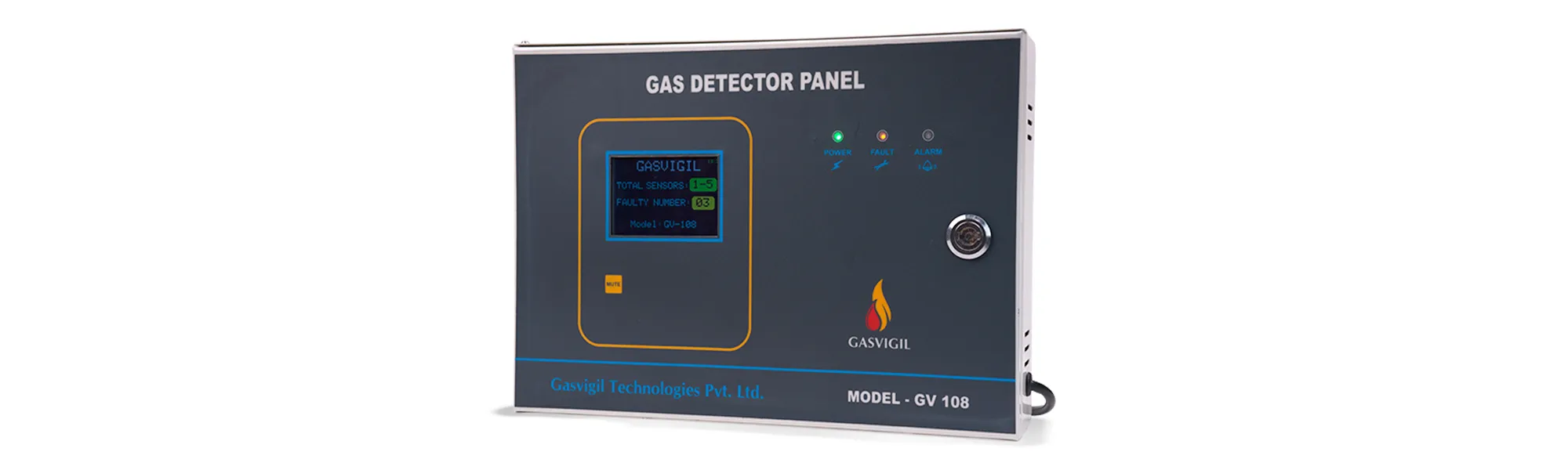

In today’s industrial landscape, gas detection is not optional—it’s essential. The GV 108 Panel by Gasvigil Technologies offers a high-precision, microcontroller-based solution for monitoring combustible gases in real time, protecting people, assets, and infrastructure.

Engineered for use in chemical plants, gas banks, boiler rooms, and commercial kitchens, GV 108 supports up to 60 addressable detectors, making it ideal for large-scale applications.

Key Features at a Glance

- Supports Up to 60 Wired Detectors

- Graphical Backlit LCD Display

- Real-Time RS-485 / MODBUS Communication

- High-Decibel Audible Siren + Visual Alerts

- Optional GSM Alerts via SMS

- Relay-Based Automation Capabilities

- Fault Detection, Mute, and Manual Override

Powered by Advanced Microcontroller Technology

At its core, GV 108 utilizes a high-performance microcontroller for real-time detection, low-latency processing, and reliable environmental analysis. It’s built to minimize false alarms while swiftly triggering response systems like fans, shutoff valves, or alarms.

Intuitive Interface & Proactive Alerting

GV 108 ensures safety personnel never miss a warning:

- Red (Alarm), Yellow (Fault), Green (Power) indicators

- One-Touch Mute and Acknowledge Buttons

- Buzzer and Relay-Triggered Alerts

The ergonomic control panel includes navigation keys (Up, Down, Enter, ESC), ensuring easy operation—even in low-light environments.

Comprehensive Sensor & Network Support

The panel connects to Catalytic gas sensors via 1Sq mm x 4 Core Cable, using diffusion-based sampling for highly accurate readings of LPG and PNG concentrations. Sensors are reliable across wide temperature ranges, ideal for rugged industrial use.

Smart Communication & BMS Integration

Featuring RS-485 and 4–20mA outputs, GV 108 can be integrated with:

- Building Management Systems (BMS)

- SCADA

- Third-party industrial control units

Its Modbus compatibility makes it a plug-and-play solution for centralized safety systems.